過電壓保護(hù)汽車系統(tǒng)-Overvoltage Protecti

It is a common requirement for electronic circuits to have to withstand some degree of overvoltage and/or reverse voltage on the power-supply lines. This is especially true with automotive systems where the main power-supply input to any particular vehicle electronic system is required to tolerate various overvoltage and transient voltage conditions, including alternator load dump. Components within the electronic system that are downstream of the main power supply are then protected from the worst of the power-supply conditions. Such components, when mounted remotely from the main electronic module, have additional wiring fault tolerance requirements due to their proximity to the vehicle's wiring loom.

Components mounted remotely from the main electronics module include sensors and actuators, which are commonly required to tolerate the application of ±16V across any combination of their exposed connections. The purpose of this test is to simulate wiring-loom faults that result in wiring shorts to the vehicle's battery connections.

Many modern integrated circuits are designed to operate from a nominal 5V power supply and do not readily accept the application of ±16V to their pins. Some kind of protection circuit is therefore needed.

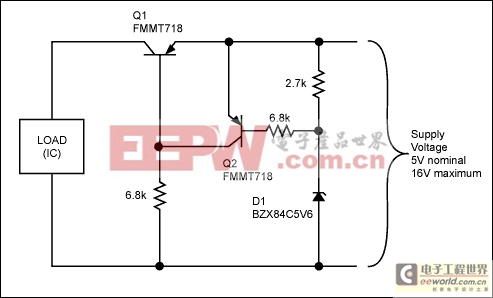

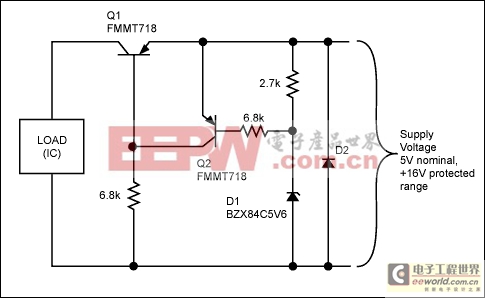

Any overvoltage protection circuit will be required to do two basic things. The first is to prevent voltages greater than the maximum allowable from being applied to the IC pins. A trip voltage value (the power-supply voltage above which the protection circuit will activate) is therefore required that will allow the system to function with normal power-supply voltages. The second task is for the protection circuit not to intrude on the normal function of the circuit. This second point is concerned primarily with power-supply voltage drops induced by the protection circuit. These are most important in ratiometric measurement systems where any power-supply voltage drop will appear as an offset in the associated measurement. In addition to these two basic points, the protection circuit must be fast enough to act on any transient events that can occur on the power-supply line. A discrete component circuit that fulfills these overvoltage requirements is presented in Figure 1.

Figure 1. Discrete overvoltage protection circuit.

How It Works

The main pass element in the protection circuit shown in Figure 1 is the PNP transistor Q1. Care should be taken in selecting this part, as any power-supply voltage drops will be determined by the characteristics of this transistor. A Zetex FMMT718 device has been used for this duty. The FFMT718 is one of a family of devices that exhibit very low VCE saturation voltage values. This minimizes the voltage drop induced by the presence of the protection circuit. The transistor Q2 acts as the control element for Q1 and will turn on (turning Q1 off) when the voltage at the power-supply input is equal to the sum of the zener voltage, due to diode D1 and Q2's own VBE voltage at a collector current of about 650uA. Q2 and D1 together produce a typical trip voltage of 5.85V at 25°C. Approximately 0.53V of this is due to the VBE voltage of Q2. The remaining 5.32V is produced across D1. Note that the zener diode D1, although a nominal 5.6V device, is being operated at a very low reverse current, about 200uA as defined by the VBE of Q2 together with the 2.7k resistor. At this current, the zener voltage is below the characteristic "knee" and is therefore less than the rated value. The 6.8k resistor connected to the base of Q1 provides the current necessary to keep Q1 turned on under normal circumstances.The circuit operates to disconnect the load during overvoltage conditions. That is to say that Q1 switches off when an overvoltage condition is detected, removing power from the load. Q1 will turn on again when the overvoltage condition is removed. One of the attractions of this type of circuit is in its response speed. The circuit in Figure 1 does not use feedback, so there are no high-order damping effects or slew-rate limitations to overcome. The full speed of the constituent parts is available to prevent transient power-supply events from reaching the load.

Q2 has been chosen, for convenience, to be the same type as that chosen for Q1, although there are no special requirements of this device and almost any PNP device could be substituted.

Reverse-Voltage Protection

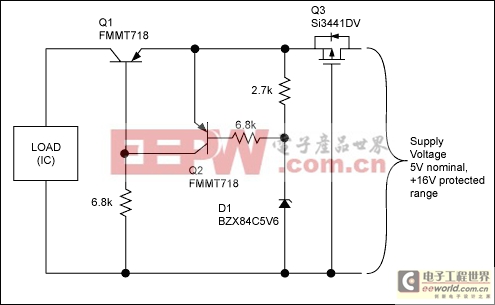

The circuit in Figure 1 will withstand reverse power-supply voltages of only about -5V. The reverse breakdown voltages of the base emitter junctions Q1 and Q2 determine this figure. Additional circuitry is therefore required to provide the (-16V) reverse-voltage protection capability. Either one of two simple additions to the circuit in Figure 1 will provide the necessary reverse-voltage protection. The first method employs a p-channel MOSFET, as shown in Figure 2. By configuring the MOSFET as shown, the device's body diode will automatically conduct when a power-supply voltage of greater than about 0.5V is present. The body diode of this transistor is a necessary feature, as without it the circuit would not start up. The addition of this component provides a disconnect function under reverse-voltage conditions. The only requirements for the reverse protection MOSFET are that it should be a low Ron, logic level type. A Si3441DV device is shown, but any similar device can be substituted.

Figure 2. P-channel MOSFET as the reverse-voltage protection element.

Circuit Performance

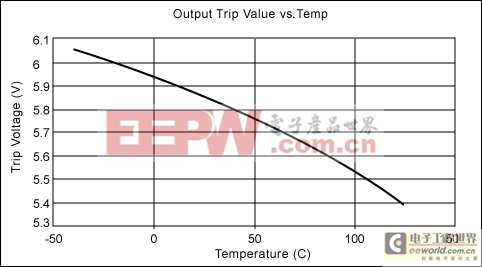

The performance of the protection circuit in Figure 2 can be ascertained from two principal measurements: trip voltage value and forward voltage drop. The graph in Figure 3 shows the trip voltage versus the temperature characteristic for this circuit. The measurements for Figure 3 were conducted using a sensor signal conditioning IC, the MAX1455, as the load circuit with a 1uF decoupling capacitor across the IC power-supply pins. The nominal current draw of the IC circuit during the test was 3mA. Examining the plot in Figure 3, we can see that the trip voltage of the protection circuit exhibits a temperature coefficient of -4mV/°C. Half of this figure is due to the VBE temperature characteristic of transistor Q2. The remainder is produced by the zener diode D1. If a more accurate trip voltage value is required (one that has less variation with temperature), then a higher-performing voltage reference could be substituted for the zener diode.

Figure 3. Trip voltage versus temperature for the circuit in Figure 2.

The reverse-voltage protection characteristic of the circuit in Figure 2 can be characterized by the reverse leakage measured over temperature with -16V applied to the power input. The results obtained for reverse-leakage performance of the circuit in Figure 2 are shown in Table 1, in which the reverse-leakage characteristic is presented as a leakage-resistance value.

Table 1. Reverse-Leakage Resistance versus Temperature

Note: The reverse-leakage current measured from -40°C to 60°C was effectively zero (infinite-leakage resistance).

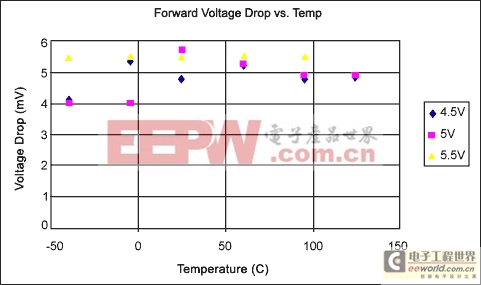

The forward voltage drop of the protection circuit in Figure 2 was measured at three supply voltages—4.5V, 5V, and 5.5V—for temperatures in the -40°C to 125°C range. The results obtained are presented in the graph in Figure 4.

Figure 4. Forward voltage drop versus temperature for the circuit in Figure 2.

Examining the results in Figure 4 shows the forward voltage drop of the circuit in Figure 2 to be below 6mV for temperatures in the -40°C to 125°C range. The effect of power-supply voltage drops on ratiometric measurement errors is the same as with any other system offsets, so long as the circuit has been calibrated with the protection circuit in place. When subjected to a 10% change in power-supply voltage, the error induced by any offset within the system will be 10% of the offset value. So, a 6mV offset (voltage drop) will induce a ratiometric measurement error of 0.6mV when the power supply is changed by 10%. In a system where the output span is set to 4V, this 0.6mV error will correspond to a measurement error of 0.015% of span.

Less Expensive Reverse-Voltage Protection

The circuit in Figure 2 uses a p-channel MOSFET as the reverse-voltage protection element. This has the advantage of disconnecting the load during reverse-voltage events and therefore places no particular requirements on the power supply. A less expensive alternative to this is to use a simple diode connected across the power supply as the reverse protection element. This arrangement is shown in Figure 5, but can be used only where the main system power supply is current-limited or fused. The diode protects the circuit by conducting whenever a reverse voltage is applied to the power-supply inputs of the circuit. The diode must be rated to withstand the maximum current or the fuse rating of the system's power source.

Figure 5. Use of a diode as the reverse-voltage protection element.

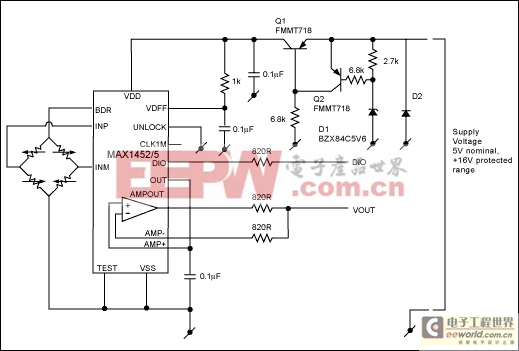

Full Sensor Signal Conditioner Overvoltage/Reverse-Voltage

Protection Circuit

Figure 6 illustrates a fully protected, sensor signal conditioning circuit using the circuits described above with the MAX1452-MAX1455 signal conditioning ICs. The circuit shown in Figure 5 protects the main power supply to the MAX1455. Series resistors provide additional protection for the signal output pins. The series resistance values are selected so as not to exceed the maximum specified pin current into the IC, with a ±16V fault applied to the signal lines.

Figure 6. Fully protected, sensor signal conditioner circuit withstands the application of ±16V to any wiring connection.

評(píng)論